In the Store-to-Store scenario, the stores are replenished from other stores. This is a common approach for one-time or seasonal items which cannot be replenished anymore after the first purchases. When the entire stock is distributed among the stores, re-balancing is needed to ensure that the items are replenished to stores with demand.

Goal

The goals of this step:

- Get a detailed understanding of the retailer's item-flow approach

- Identify different item-flows for different product groups and stores

- Create an item-flow drawing

- Set up Replenishment Templates and Journals in LS Central.

Key questions / considerations

General

- Which product groups are redistributed between stores?

- Does this apply to all stores?

- If no:

- Are some stores excluded from redistribution?

Calculation

- How shall the system identify distributable stock in the stores?

- Predicted end-of-life stock?

- Parameter driven (Reorder Point and Max. Inventory)

- Balancing stock across stores

- If stock exists in the stores and the warehouse, how should the warehouse stock be treated?

- Ignore warehouse stock

- Prioritize warehouse stock

- Treat same as store stock (use Redistribution Matrix to find best location combinations)

- How shall the system calculate and optimize the Transfer proposals?

- Least (transportation) cost between the stores

- Least distance

- Least duration.

For more information on

- how the system calculates distributable stock, see Redist. Calculation Types.

- how the system calculates and optimizes the Transfer proposals, see Redist. Strategies.

- how warehouse stock is treated, see Warehouse.

Output

-

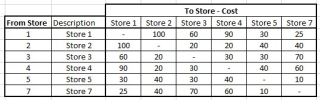

Redistribution drawing (allowed routes):

-

Redistribution matrix (allowed routes and cost):

LS Central setup considerations

Redistribution Matrix

Store Stock Redistribution depends on a definition of which stores are allowed to transfer items to which stores. This concept is called the Redistribution Matrix and this matrix holds a list of locations, and the transportation cost, distance, and duration between them.

For more information see Redist. Matrix.

Replenishment Templates and Journals

Replenishment Journals are used to calculate Transfer Order proposals for Redistribution.

Each Journal has a Template and a Batch:

- The Template defines what and how the Journal should calculate - it defines the item flow and provides filters for items, stores, vendors, and more.

- The Batch defines when the Journal should be calculated.

For the Store-to-Store approach you create Templates with the following settings:

- Replenishment Type is set to Redistribution.

- Redistribution Calculation Type is set to the type how the system calculates redistributable stock.

- Redistribution Strategy is set to the strategy for how the Transfer Order proposal is calculated.

If you detect in the analysis that not all items or stores are using this approach, you must filter the Template to the desired items and locations. The Template provides filters for:

- Vendors

- Item based filters (Division, Item Category, Product Group, Special Group, ...)

- Location based filters (From-Locations and To-Locations to be considered).

The calculation frequency is set up in the Replenishment Batch. If stores are replenished on different days, then it is best practice to create multiple Templates that contain stores with the same interval.

For example: stores A and B are calculated on Monday, store C is calculated on Wednesday. You would create two Templates with filters for the stores and set up the batches to reflect the frequency.

For more information on how to set up and use Store Stock Redistribution see:

Go back to: